|

Guangdong Hynov Technology Co.; Ltd

|

The heat recovery case of tail gas of Curing Furnace for drying

| Price: | 7000.0 USD |

| Payment Terms: | L/C |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The nanometer Calcium fly produced by this factory contains water, which needs to be dried. This factory used the steam to exchanger hot wind

XINGLONG BUILDING MATERIAL MANUTACYURE

—The heat recovery case of Curing Furnace's tail gas for drying

The ceiling drying line of this factory used the electricity to heat in previous, only 2 drying lines would consume electricity over 20,000 kilowatt-hour.

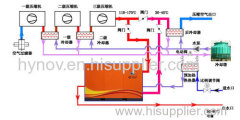

The process temperature requirements of ceiling drying line require is 90-100℃. And the tail gas temperature of Curing Furnace, which is beside the production line, is 110℃. While it has great recycling value,it is emitted directly, which wastes heat energy and pollutes the environment.

After the analysis of HYNOV Technology engineers, we suggest them use the flue gas-to-air heat exchanger to recover the tail gas's waste heat, and uses it makes hot wind for drying and replaces the electricity to supply heat.

The project combines the waste heat recovery and damp proofing technology, we can get a better drying effect, while the drying temperature only needs to be controlled in about 90℃.

The transformation of 2 drying lines can save 180,000 Yuan every year. If we transform 4 lines as planned, they can save 320,000 Yuan every year.